Have a chat with us at Hall 8, Booth E64 at the Battery Show Europe in Stuttgart, Germany, and discover the latest developments in the advanced battery and automotive industry.

Discover event

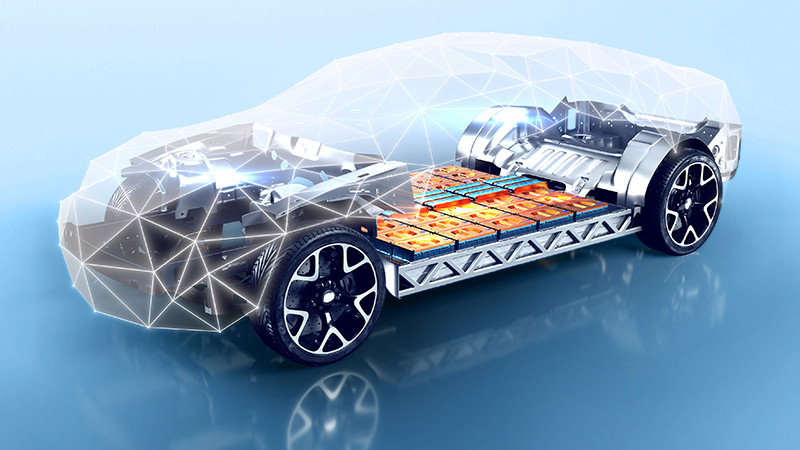

Lithium-ion cells have become an indispensable part of the modern mobile world, from smartphones to electric cars – here, BYK additives are of great importance, as they make the production process more efficient and ensure better product properties. In the manufacturing of Li-ion batteries, for example, the good dispersion of particles is crucial for the performance, as is the control of interfaces and the perfect coating of substrates. Additives BYK supplies to this market are mainly used in the production of electrodes and ceramic-coated separators.

Wetting and dispersing additives from BYK make it easier, for instance, to disperse conductive carbons like carbon black and carbon nanotubes (CNTs). This allows the production of homogeneous electrode slurries for an improved anode and cathode manufacture. The viscosity of these slurries based on lithium iron phosphate (LFP), lithium nickel manganese cobalt (NCM), lithium nickel cobalt aluminum (NCA), or various other active materials can also be reduced significantly. Besides, BYK’s wetting and dispersing additives are also applicable for the dispersion of ceramic materials like alumina and boehmite in separator coatings.

Surface additives, in turn, optimize substrate wetting and leveling by reducing surface tension, thus ensuring a fast and defect-free coating of separators. The BYK additive portfolio is rounded off by tailor-made defoamers, rheology additives for adjusting flow behavior, and binders for enhancing adhesion strength, mechanical resistance, and heat resistance.

Have a chat with us at Hall 8, Booth E64 at the Battery Show Europe in Stuttgart, Germany, and discover the latest developments in the advanced battery and automotive industry.

Discover event

If you have any questions, need additional information, or would like to order samples, we are happy to help you.

Contact

Additives for Energy Storage

Go to brochures

Innovation competence around the battery cell: ALTANA bundles its competencies in the battery sector.

View video