Additives for Inket Inks

Go to brochures

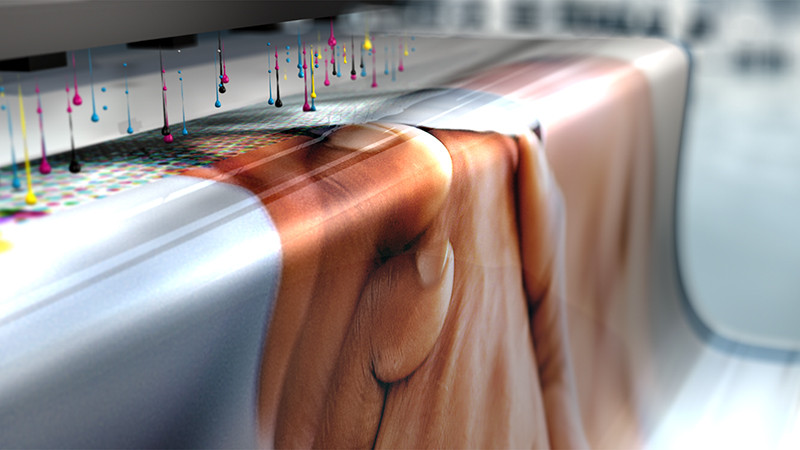

Inkjet printing is becoming increasingly important in many areas in which substrates have traditionally been printed using exclusively conventional means, e.g. in packaging printing on paper, cardboard and foil, on ceramic substrates or on textiles. For all applications, BYK offers the fitting additives to support the formulation of inkjet inks, even in areas in which indirect contact with food is required. BYK additives ensure low-viscosity and long-term stable inkjet inks with optimum color strength, improve the jetting properties and abrasion resistance of aqueous, radiation-curing, solvent-borne and ceramic inkjet inks.