If you have any questions or need additional information, please do not hesitate to contact us:

Contact

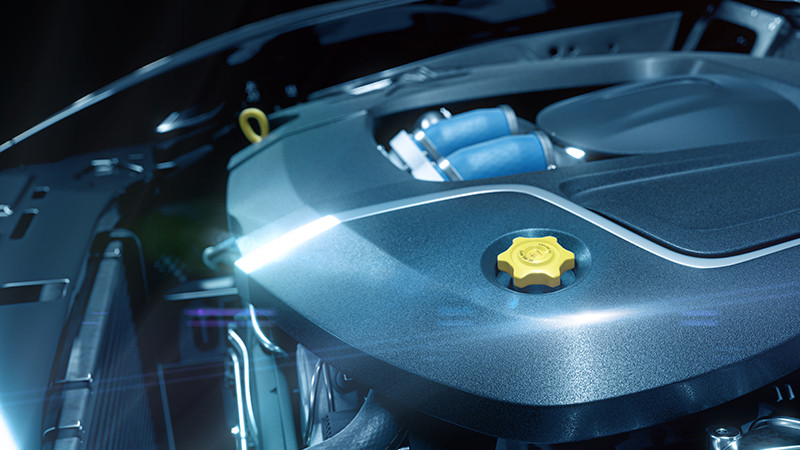

Thanks to their versatility, thermoplastic materials are in high demand and are used in a large variety of industries and applications worldwide, from the automotive industry to electrical and electronics products and appliances, from the construction business to film and packaging. For industrial applications such as cables, food packaging or structural components, BYK offers manifold performance solutions including thermal stabilization, flame retardancy, processing aids, UV stabilization, and nucleation. In the area of thermoplastics for the transport industry, we are a reliable partner for your automotive applications, providing coupling agents, high performance reinforcing materials, thermal stabilizers, and one-pack solutions.