- Additives

- Instruments

Synthetic phyllosilicates also belong to the group of powdered inorganic rheology additives used in aqueous systems. The main difference to the natural phyllosilicates is the origin of the products.

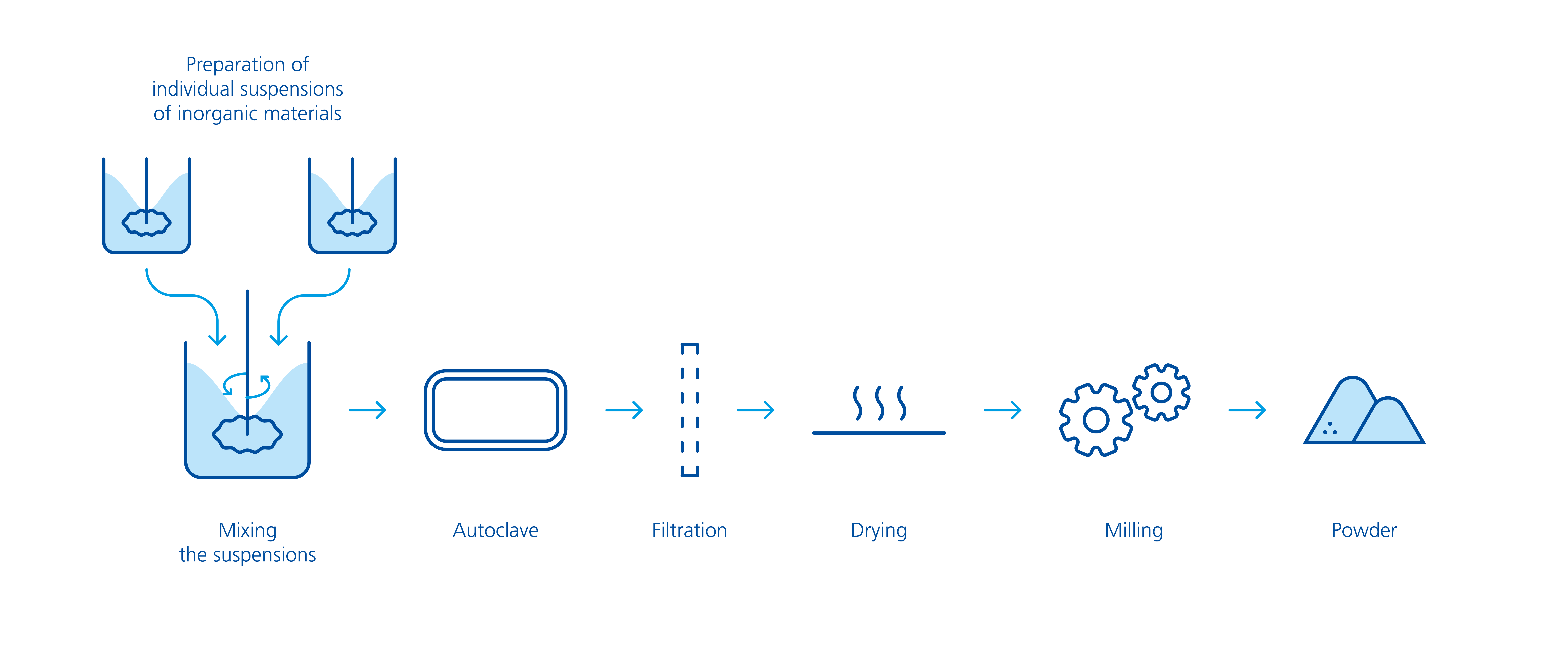

Synthetic phyllosilicates are manufactured from naturally occurring inorganic minerals. Different products are available within this product class for performance in many applications such as orientation of effect pigments, storage stability, film formation, anti-static or multi-color effect. These different products can also offer improved value in handling and processing as well as efficiency. Furthermore, they are uniquely characterized by high purity and consistency, ensuring repeatable performance and exceptional clarity.

Synthetic phyllosilicates can be delaminated by uniform stirring, whereas the delamination of natural phyllosilicates requires higher shear forces. For this purpose, the synthetic phyllosilicates are first incorporated in water and then processed directly (in-situ) or as a semi-finished product. A difference is made between two types of synthetic phyllosilicates - the powder and the sol types. With the powder products, semi-finished products of varying concentration (up to 10 %) are produced in water. Depending on the dosage and the hardness of the water used, the semi-finished products can be used in liquid state for different lengths of time before they form a gel and could lead to seeds in the finished system. All other components of the formulation are only subsequently incorporated into the semi-finished product.

In contrast, sol types can be used to produce much more highly concentrated, storage-stable semi-finished products (up to 25 %), since phosphate ions block the rheological effectiveness. During incorporation, formulation components such as pigments and fillers adsorb the phosphate ions and the product becomes rheologically effective. Preformulated liquid sol types are available, as well as the powdered starting products. The latter are suitable for the production of own semi-finished products of different concentrations. Sol types are characterized by the fact that the semi-finished products can also be subsequently incorporated into a formulation. Restrictions may arise in terms of resistance (whitening), depending on the system.

Synthetic phyllosilicates also become rheologically effective through the formation of a three-dimensional structure (the so-called house of cards effect). Compared to the natural phyllosilicates, they are characterized by a significantly smaller particle size (25 nm) after delamination. This leads to a significantly higher number of phyllosilicate platelets at the same dosage and thus to faster structure formation and greater effectiveness. Additionally, the smaller particle size also results in a significantly smaller influence on the gloss retention. A major advantage of the synthetic phyllosilicates is the variation of the flow behavior from strongly thixotropic to strongly pseudoplastic depending on the dosage used.

Thixotropic flow behavior occurs at a low dosage (<0.5 %), since fewer particles take longer to build up a structure. At higher dosages

(>1.5 %), on the other hand, pseudoplastic flow behavior occurs, since a larger number of particles also builds up the structure more quickly. Due to the wide range of possibilities for adjusting the flow behavior of synthetic phyllosilicates, they can be used in a very wide range of applications. This applies to both low viscosity and high viscosity formulations. These include, for example, the orientation of effect pigments in the automotive sector, but also high-viscosity effect applications such as multi-color paint (MCP). There are also a wide variety of applications in home care and personal care applications, such as cleaners or toothpaste.

If you delete your search history, all your previous searches will be deleted permanently.