- Additives

- Instruments

Wesel, February 21, 2018 – BYK-C 8013 is a solvent-free, polymeric coupling agent for improving the mechanical strength of carbon-fiber-reinforced, radical-curing systems, and it is the world’s first coupling agent for carbon fibers.

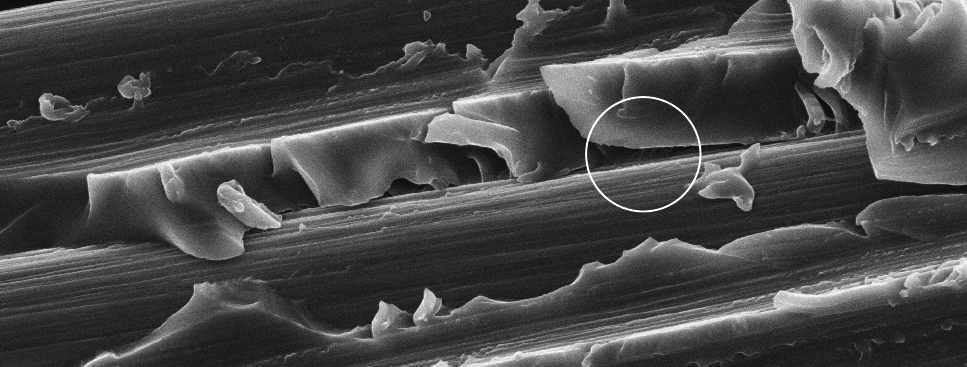

It is used in vinyl esters and unsaturated polyester resins that are processed to composite parts using carbon fibers. The cross-fiber strength is greatly improved, making far greater design freedom possible.

BYK-C 8013 increases both the transverse tensile strength and the flexible strength of the composite by means of improved fiber-matrix bonding. The chemical structure of the additive provides simultaneous adhesion to the fiber and to the resin matrix. This unique property makes changes in the component design possible, and it enables particularly durable components to be manufactured. Especially in hot-curing processes such as SMC/BMC, pultrusion, prepreg or RTM, BYK-C 8013 brings about increases in strength of up to 70 percent.

Coupling effect with BYK-C 8013

The reactive additive can be introduced to the size during fiber production or to the resin shortly before processing. In subsequent, so-called “second sizing”, BYK-C 8013 can, for example, be applied to the fiber in a spraying process, without the need to remove the first coat beforehand.

This innovative additive will be unveiled and premiered before a trade audience at Booth E40 in Hall 5a of the JEC in Paris from March 6 to 8.

More information on byk.com/jec.

Press Releases | February 21, 2018

BYK is a leading global supplier of specialty chemicals. The company’s innovative additives and differentiated solutions optimize product and material properties as well as production and application processes. Amongst other things, BYK additives improve scratch resistance and surface gloss, the mechanical strength or flow behavior of materials, and properties such as UV- and light stability or flame retardancy. In the field of quality assurance, BYK’s measuring and testing instruments serve to effectively assess appearance and physical properties.

The company’s customers include manufacturers of coatings and printing inks, plastics, adhesives and sealants, as well as cleaners, floor coatings, and lubricants. BYK additives are also successfully used in the construction chemistry, oil and gas, and foundry industries.

BYK has a global network of subsidiaries and operates production sites in Germany (Wesel, Kempen, Moosburg, Schkopau), the Netherlands (Deventer, Nijverdal), and the UK (Widnes), in the USA (Wallingford, Chester, Gonzales, Louisville, Earth City and Pompano Beach), and in China (Tongling).

The company is part of the ALTANA Group and employs a workforce of more than 2,300 people worldwide.

If you delete your search history, all your previous searches will be deleted permanently.