- Additives

- Instruments

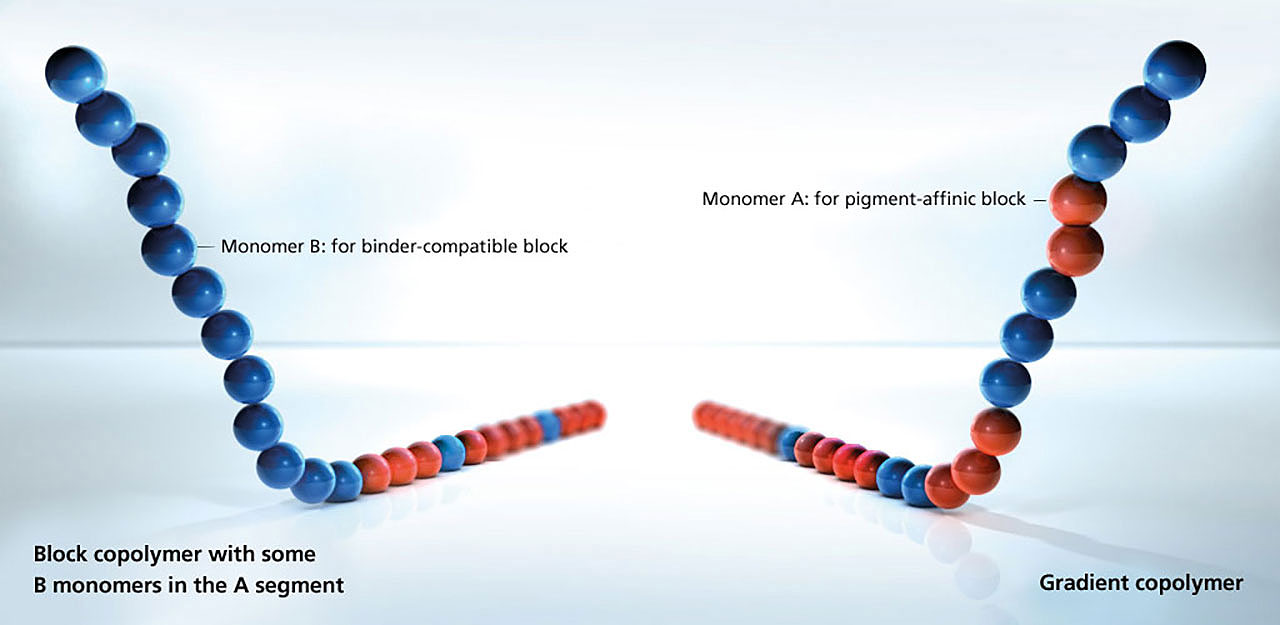

To synthesize effective additives, not only must the appropriate number of monomers for the pigment-affinic groups and the binder-compatible chains be selected, but their arrangement in the copolymer is also crucial. If the individual components are statistically distributed along the chain, the additive effect that is desired will not be observed. Block structures are more favorable for wetting and dispersing additives. These comparatively simple structures can be modified to include a lot more intricacies and details:

the segments consisting of A monomers (pigment-affinic groups) do not need to be compatible with the binder system, because the B segments are responsible for this compatibility. However, if their incompatibility is too great, the handling of the products becomes difficult and the efficiency is reduced. Therefore it can be beneficial to have some B monomers within the A segments in order to improve the compatibility. Another possibility is to reduce the sharp transition between an A and a B block by creating smoother transitions: the concentration of A monomers reduces along the polymer chain while the B monomers increase (gradient copolymers).

The knowledge about interactions between the structure of copolymers and their efficiency is only helpful when it is possible to reproduce the complex copolymer structures not only in the laboratory but also under production conditions. And in this respect, the situation today looks much better than it did in the past. For some years now, modern polymerization methods (ATRP, NMP, C-RAFT, S-RAFT, GTP) have been available to provide a very high control of the structure of copolymers. These methods (the first four are often summarized as “CRP”, controlled radical polymerization) all have their specific features and advantages/disadvantages and can be used to polymerize a wide range of monomers under controlled conditions. DISPERBYK‑2000 and DISPERBYK‑2001 were our first wetting and dispersing additives produced by controlled polymerization (GTP) and were introduced in 1999. Newer products make full use of the possibilities that modern CRP methods offer today. And it isn’t just the sequence succession in the block copolymers that can be better controlled and reproduced, but also the molecular weight distribution has become considerably tighter which, for example, makes it easier to handle the additives.

If you delete your search history, all your previous searches will be deleted permanently.